REEL HANDLING EQUIPMENT: HOW CAN REELS BE HANDLED ERGONOMICALLY AND FUNCTIONALLY?

Raw materials and operating materials are often rolled up in production – from packaging material for shipping, to plastic films for the production of sealed products, to textiles in clothing production. On reels and rolls, these materials can be compactly stored and cleverly processed.

But reel handling is not only cumbersome, it is also physically stressful. Reel manipulators help to turn and tilt effortlessly – so that your production continues to roll ahead without interruption.

WHAT ARE REEL MANIPULATORS USED FOR?

In industrial contexts, reels are usually too heavy and too bulky for manual handling. For this reason, it is advisable to use reel lifters and other reel handling equipment, as well as roll lifting equipment and roll handling equipment to relieve the physical burden on employees.

Reel manipulators not only lift and move reels manually or electrically, but can also tilt and turn them. This is necessary when assembling and changing reels at workstations and machines.

A reel manipulator accomplishes the task of ergonomic and effective reel handling, both affordably and flexibly. Compared to automation by robots and conveyor technology, it requires less investment. As an alternative to manual handling, a manipulator eliminates the risk of accidents and ill health.

WHAT IS A MANIPULATOR?

Manipulators are often associated with industrial robots. Their task is to enable the object to be manipulated to interact with the surrounding environment. In the case of a reel manipulator, the goal is to physically position reels of packaging material, composites, films and other materials such that the material can be further processed and used.

A manipulator is the movable part of a device that performs its mechanical work. In order to support the handling of reels, the reel manipulator is mounted, for example, on a reel lifter. In this way, the lifting device can perform other tasks, such as turning and tilting the reel, in addition to lifting and transporting.

SUITABLE GRIPPING DEVICES

The lifting aid requires appropriate gripping equipment so that the transfer of reels to different positions can be carried out safely and in a careful manner. There are various ways to do this when handling reels:

- A simple boom can pick up the reel from the inside of its core. Booms can be supplied in different lengths and with a specific diameter. The diameter of the reel core must therefore correspond at least to the diameter of the boom.

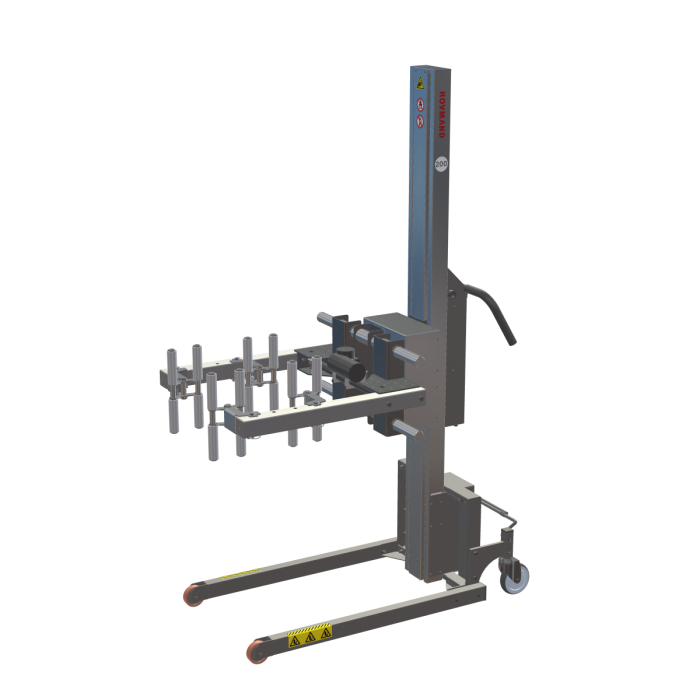

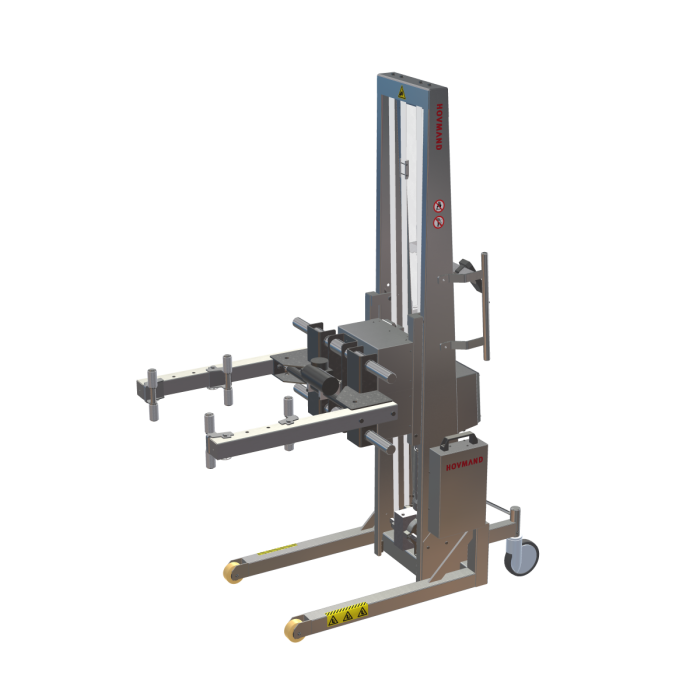

- Grippers include a double boom, which can lift the corresponding reel from below. This solution is suitable for particularly heavy reels and reels with a large diameter. For standardised reel sizes, a double boom with fixed boom spacing is sufficient. A flexible double boom can be used for applications that require adjustment to different reel sizes.

- Electric reel grippers have the ability to grip reels of various sizes from the outside, making them extremely flexible. In addition, depending on the model, electric reel grippers can electrically grip, turn and tilt reels up to certain weights – without any human effort.

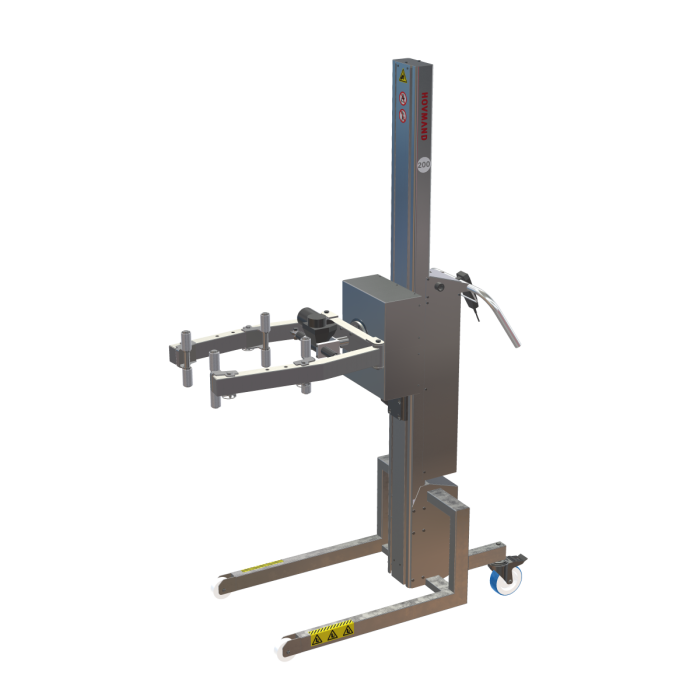

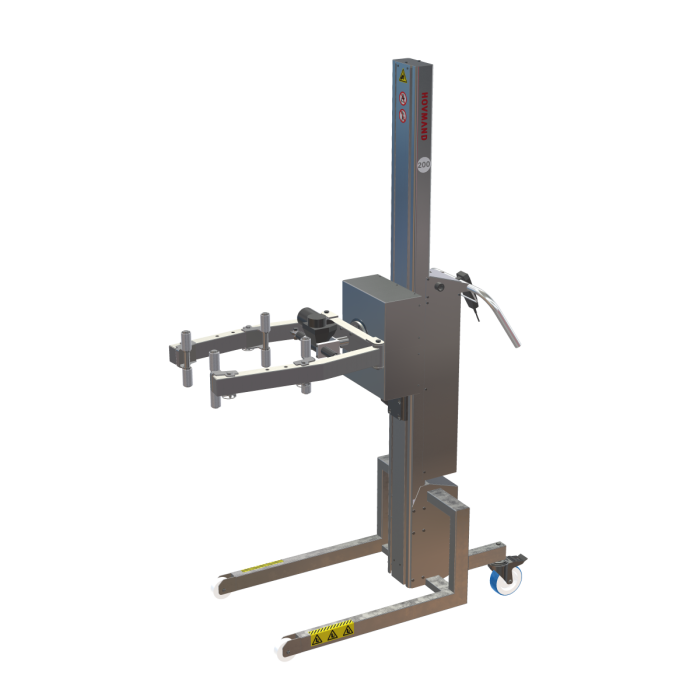

- Manual manipulators accept reels with defined dimensions and weights and can be manually tilted horizontally with lever force.

- Finally, electrical reel manipulators tilt the reels to horizontal positions. In this way, it is possible to move even very heavy reels weighing up to 200 kilograms.

Hovmand’s reel lifters are individually adapted to the requirements of our customers, according to a modular system. When designing a suitable reel lifter, various gripping devices can also be combined on one lifter.

AREAS OF APPLICATION FOR REEL MANIPULATORS

The application possibilities for reel manipulators are many. Wherever the logistics or production process includes positioning tasks, a suitable reel manipulator variant will come in very handy. Manipulators support daily work in the following situations:

1. Packaging processes in production

Reels are often applied at the end of the production process. They hold, for example, plastic films or paper for the packaging of finished products. The use of a reel lifter with manipulator or paper roll lifting equipment, in particular, can be advantageous when filling such reels. The reel is thereby transported from the warehouse to the place of use, where it is put in the right position to be mounted on the packaging machine or the workstation.

Impact 130-3 – for improved ergonomics of packaging

Impact 130-3 is commonly used to handle reels of packaging materials, such as plastic film and paper. It makes it very easy to accurately position, load and unload reels of packaging materials from pallets and racks. It also ensures seamless transportation to the packaging machines.

Impact 200-3 – for heavier reels or more complex tasks

Impact 200-3 extends the capabilities of the Impact 130-3, offering more power, which is suitable for more demanding tasks, especially with the Grip & Turn EG6-tool. With its high lifting capacity it is ideal for heavy reels. It features adjustable lifting heights and tilt and rotation functions, along with a range of adaptable gripping tools.

2. Order processing in distribution

Reels containing plastic shipping bags, for example, are used when shipping customer orders. Filling material made of plastic or paper is also often stored on rolls. At the corresponding workstations, they are filled with air and placed in shipping boxes for protection. In addition, shipping or return labels are printed – which also come on reels. Reel changes occur very frequently in the shipping department, in particular.

INOX 90-3 – hygienic and easy order processing

The INOX 90-3 is designed to optimise order processing in distribution centers. Its high-quality stainless steel also makes it suitable for hygienic environments, supporting frequent and efficient reel changes. It simplifies the task of moving, loading, and positioning reels at packaging stations.

INOX 200-3 – a hygienic solution for heavier reels

INOX 200-3 is a robust reel lifter that enhances order processing with its ability to manage heavier reels, thanks to its high lifting capacity. You can easily adjust the lifting height and tilt and turn capabilities with various gripping devices. It is also made of high-quality stainless steel, making it ideal for hygienic environments.

3. Punching, welding and cutting tasks in production

Certain products are based on punching, cutting or welding goods sold by length. This applies to textiles as well as paper, cardboard, plastic and even metal – called coils. The compact and space-saving reels are usually used for the delivery and storage of such materials. Production machines for converting plastic films into freezer bags or flat metals into Christmas ornaments are often set up so that they can further process the raw material from the reel. Therefore frequent reel changes are also necessary here – not only when emptying a reel, but also when converting the machine from one product to the next.

E300 – power for the heaviest reels

The electric E300 lifter with an impressive 300 kg lifting capability is ideal for high-load, high-frequency tasks, particularly when outfitted with the Grip & Turn EG6-tool. The powerful reel lifter and manipulator can handle the heaviest reels of raw materials (such as metal coils, plastic films, and textiles).

HOW DOES A REEL MANIPULATOR WORK?

In order to be able to turn and tilt reels precisely, the various elements of the manipulator must work together perfectly. These include:

- The basic reel lifter with its load-bearing column

- The grippers with the corresponding axes, which allow the reel manipulator to turn reels in the desired direction

- The controller that ensures that the manipulator responds accurately to the operating components

First, the reel is placed on the boom or between the grippers of the reel manipulator. When this is happening, it is important that the reel is held securely enough and handled carefully at the same time, so that its contents are not damaged.

The user then controls the reel manipulator either manually via lever force and pressure, or electrically.

The manipulator drive now tilts, rotates or moves the reel in the desired manner with the appropriate force. For example, reels with plastic film for packaging are stored upright on pallets.

The reel is gripped and lifted with the boom of the reel lifter. The reel turner now turns the reel 90 degrees so that it can be moved horizontally to the shipping department.

Here, the reel can be pushed from the boom of the manipulator onto the axis of the packaging machine in the current position.

HOVMAND ROLL HANDLING EQUIPMENT

At Hovmand, we design tailor-made solutions for handling rolls. We have plenty of experience to know the diverse areas of application for rolls. Efficient and ergonomic handling is particularly important here, as manual pushing, pulling, rolling and lifting can not only be extremely harmful and stressful, but also ineffective for a particular process. Moreover, the rolled up material will be damaged if improperly handled.

That’s why we value flexible and individual solutions for manufacturing and logistics. Hovmand’s reel lifters and reel manipulators (including reel turners and roll turners) along with roll handling equipment, roll lifting equipment, and paper roll lifting equipment, allow easy and careful handling of reels and rolls using just a few configurable lifting aids.